How ethical manufacturing becomes a trust pass for sportswear brands ?

- Share

- publisher

- Eationwear

- Issue Time

- Jul 25,2025

Summary

In the sportswear industry that emphasizes "health" and "vitality", the brand's moral background is becoming a more important competitive advantage than fabric technology.

When you fasten the buckle of your sports bra to prepare for yoga class, or put on a fleece sweater to go for a morning run, have you ever thought about the stories behind these sports equipment? Who completes each stitch in front of the sewing machine? Is their working environment safe? Can the salary support a decent life?

Today, these issues are no longer the obsession of a few environmentalists, but a common concern of sportswear consumers around the world. Survey data from the European and American markets show that 73% of millennials and Generation Z consumers are willing to pay a premium of more than 10% for brands that focus on ethical production. In the sportswear industry that emphasizes "health" and "vitality", the brand's moral background is becoming a more important competitive advantage than fabric technology.

1. Fair labor: the first stitch of trust

The production chain of the sportswear industry often spans multiple countries, from fabric factories in Southeast Asia to garment workshops in South Asia. The difference in labor costs drives industrial migration, but also buries the hidden dangers of labor rights. Fair labor practices are the foundation for brands to build trust with consumers.

Fair labor is not an empty slogan, it is reflected in specific details: Are child labor and forced labor prohibited? Is it guaranteed that the working hours per week do not exceed 48 hours? Are workers provided with a safe working environment and medical insurance? When brands turn these promises into practical actions, consumers can feel that "this clothing not only makes me healthy, but also makes the producer decent."

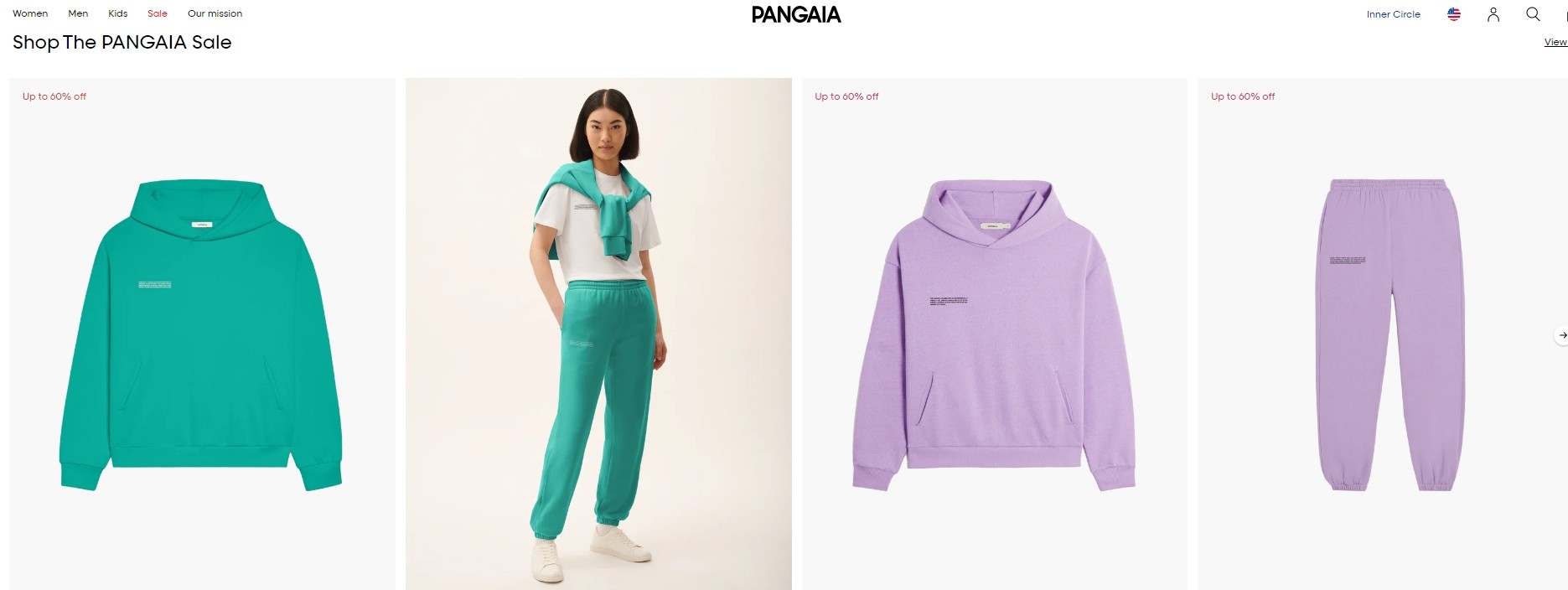

British sports brand Pangaia is a model in this regard. They focus on environmentally friendly sports T-shirts and sweatshirts. They not only disclose the list of all cooperative factories, but also regularly publish third-party audit reports to disclose in detail the workers' hourly wages, vacation system and safety training. More specifically, they will invite consumer representatives to visit cooperative factories in Bangladesh, so that "fair labor" can be transformed from an abstract concept into a real smile on the faces of workers. The trust brought by this transparency has made them a "phenomenal brand" among the environmental movement in Europe and the United States within just 5 years of their establishment.

2. Transparent production: tear down the wall between brands and consumers

Information asymmetry is the biggest enemy of trust. When consumers are confused by the vague "Made in China" or "Made in Vietnam" on the label, there is an invisible wall between the brand and them. And the transparent production process is the bulldozer that demolishes this wall.

Transparent production means that brands should disclose key information in the production process, just like disclosing sports technology patents: which supplier does the fabric come from? Does the dyeing process use environmentally friendly dyes? How to control carbon emissions? The American outdoor brand Outdoor Voices has a creative approach. They have opened a "Production Map" column on their official website. Consumers can click on the QR code on the clothing tag to see the entire process of this yoga pants or quick-drying clothes from cotton planting to finished garments leaving the factory, including the person in charge of each link and environmental protection indicators.

This "no dead angle" transparency, on the contrary, allows consumers to better understand the pricing logic of the brand. A consumer shared on social media: "Knowing that the dye of this yoga pants has been tested for non-toxicity and workers can get $15 per hour, I feel it is worth spending $80 to buy it."

3. Ethical manufacturing is not a cost, but a long-term investment

Many brands are worried that practicing ethical manufacturing will increase production costs and affect price competitiveness. But the opposite is true. Ethical manufacturing is an investment that can bring long-term returns. The brand trust it accumulates will be converted into amazing repurchase rates and customer loyalty.

The story of Patagonia has long become a classic case in business textbooks. Since the 1990s, they have openly opposed sweatshops and insisted on using organic cotton instead of traditional cotton to produce fleece and jackets (reducing the harm of pesticide use to workers' health). At that time, this decision increased their production costs by 30%, but founder Yvon Chouinard said: "We don't want to make money that makes our conscience uneasy."

Today, Patagonia's customer retention rate is 2.5 times the industry average. Their "Worn Wear" recycling program allows consumers to send their old jackets back to the brand for refurbishment instead of discarding them directly. This deep trust has brought 47 years of revenue growth. Even during the global epidemic in 2020, their sales rose by 15% against the trend.

4. Case Analysis: How Reformation Reshapes Sportswear with Ethical Manufacturing

In a yoga studio in Los Angeles, it's hard not to notice Reformation's sports series. This brand, with the slogan "the antonym of fast fashion", has redefined sportswear with ethical manufacturing. Its yoga suits and sports bras have become a regular feature of Hollywood stars' street snaps.

85% of Reformation's sports fabrics come from recycled plastic bottles and discarded fishing nets. The "Environmental Impact Index" is printed on the hangtag of each piece of clothing, detailing the amount of water consumed, carbon emissions, and resources saved during the production process. In their own factory in Los Angeles, they have achieved 100% clean energy power supply, and workers enjoy an hourly wage that is 35% higher than the California average. The workshop is also equipped with an air purification system and ergonomic workbenches.

These practices have been made into a "moral report card" by Reformation and posted on its official website. It even frankly announced the process of a batch of sports bras being destroyed due to defects in sewing. This sincerity touched consumers. The brand's sports line contributed 30% of revenue in just two years after its launch, and the repurchase rate reached 62%, far exceeding the industry average of 40%.

5. Trustworthy Partner: Eationwear's Conscientious Production

For sports brands that want to do conscientious production, it is particularly important to find reliable suppliers. China's Eationwear is a good example. It can not only guarantee product quality, but also insist on doing good things, and can help global brands handle all aspects from design to production.

When it comes to protecting workers' rights, Eationwear is not just talking. They have passed the BSCI B-level certification, which is already a very impressive achievement in the industry. In order to reduce the physical burden of workers, the factory has equipped more than 500 employees with intelligent hanging production lines, so that they no longer have to move around and get tired like before. The production environment in the workshop is also very safe, meeting the OEKO-TEX® Standard 100 standard, and the clothes made are completely fine to wear close to the body. What's more rare is that they take the initiative to provide job opportunities for people with disabilities, and have also set up a profit-sharing system so that front-line workers can really enjoy the benefits of brand development. Contact now.

Conclusion: Let ethics become the "invisible fabric" of sportswear

The essence of sportswear is to help people live a better life, and a truly excellent sportswear brand should extend this "better" to every link in the production chain. When fair labor becomes standard and transparent production becomes the norm, ethical manufacturing will be like an invisible fabric, integrated into the brand's DNA.

For consumers, choosing sportswear that focuses on ethical manufacturing is to vote with consumption and support a fairer world; for brands, practicing ethical manufacturing is not a stopgap measure to cater to trends, but to establish a trust barrier that crosses the cycle. After all, brands that allow consumers to wear and buy with peace of mind can go further.

Next time when you choose sports equipment, you might as well take a closer look at the story behind the label - those details about fairness, respect and responsibility may be more worth paying for than any technological parameters.

Includes a short T-shirt and matching gym shorts, providing a coordinated and fashionable workout outfit.

The fabric offers excellent elasticity, allowing full freedom of movement for yoga, running, cycling, and gym training

Each skirt features attached compression shorts with silicone grippers at the hem. They stay invisible under movement while preventing accidental exposure during high-intensity drills, golf swings, or lunges.

The skirt features a classic pleated design that adds a touch of elegance and ensures maximum comfort and freedom of movement.